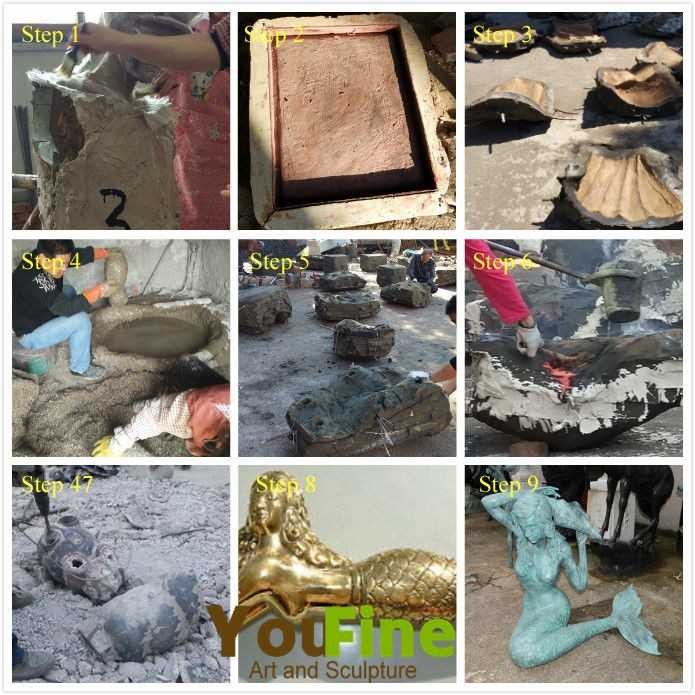

1.Make the clay mold

We would make the clay mold,according to final confirmation of the pictures from customer.

We would send the mold photos to customer until customer are satisfied with the clay mold, and say “yes”,then we go ahead.

2.Make the Silicone rubber/plaster mold

Painting the Silicone rubber /plaster onto the original clay mold.

But the Silicone rubber mold is used for small delicate sculptures.The large sculptures will create plaster mold.

3.Wax Mold

When the Silicone rubber/plaster mold dry, pour liquid wax on the inner surface.

4.Make the shell

Wax pattern will be repeated immersion in the slurry about nine times,and then coated with several layers of silica sand.

When it dry sand shell is finished.

5.Lost wax

The shell will place in the fire kiln where the shell is solidified and the wax pattern is melted out in about 12 hours.

6.Casting

Bronze material will melt into liquid in a furnace , then we will pour bronze liquid into this hollow sand shell.

7.Welding

When the bronze is cooled, remove the sand shell, weldding all parts of the sculpture together.

Polishing the surface and get ready to make paint the color.

8.Coloring

We will use the chemical color until the customers are satisfied with color, finally wax it to protect the sculpture.